When the need is aortic, the solution is Artivion.

Our intentional focus on the aorta and collaboration with the world’s foremost cardiac and vascular surgeons allow us to leverage our combined expertise in the development of new, innovative, life-changing aortic-centric technologies. Explore our end-to-end aortic-centric product portfolio.

*Note: All products and indications are not available/approved in all markets. Please contact your local Artivion representative for details.

Select Your Market

Heart Valve Solutions

On-X®

Aortic Heart Valve

On-X®

Mitral Heart Valve

On-X®

Ascending Aortic Prosthesis

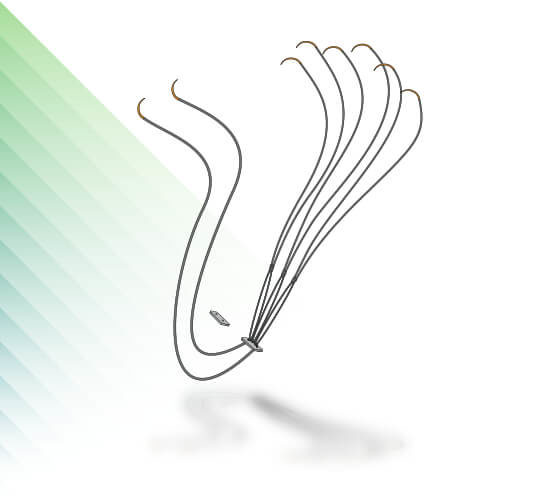

Chord-X®

Mitral Chordal Replacement Products

CryoValve® SG

Pulmonary Human Heart Valve

CryoValve®

Aortic Allograft

Allografts

Cardiac & Vascular

CryoValve® SG

Pulmonary Human Heart Valve

CryoValve®

Aortic Allograft

CryoPatch® SG

Pulmonary Patch

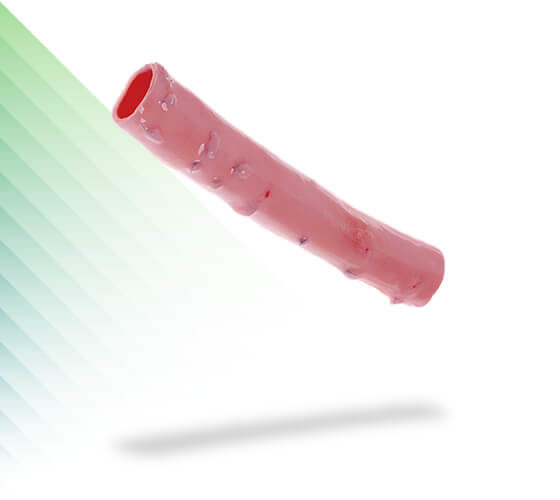

CryoGraft®

Descending Thoracic Aorta

CryoArtery®

Aortoiliac Artery

CryoArtery®

Femoral Artery

CryoVein®

Saphenous Vein

CryoVein®

Femoral Vein

CryoVein® PC

Pediatric Conduit

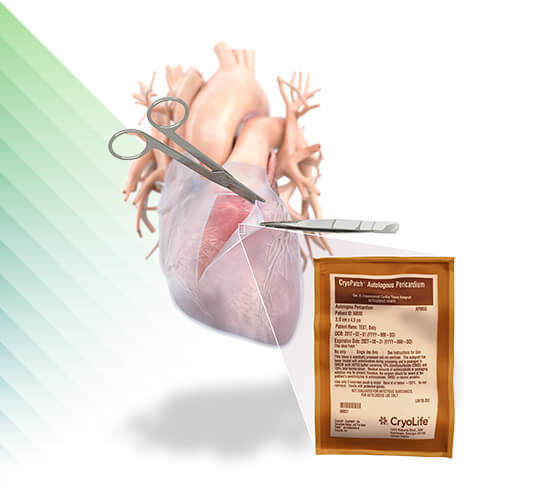

CryoPatch®

Autologous Pericardium

Surgical Sealant

BioGlue®

Surgical Adhesive

Cardiac and Vascular Ancillary Solutions

PhotoFix®

Decellularized Bovine Pericardium

CarbonAid® & CarbonMini®

CO2 Diffuser

Heart Valve Solutions

Aortic Arch Solutions

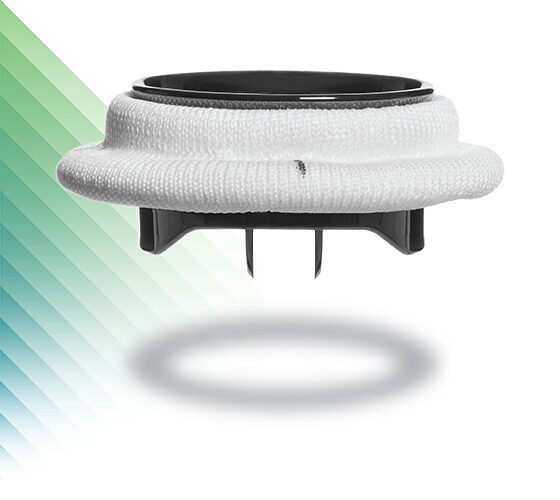

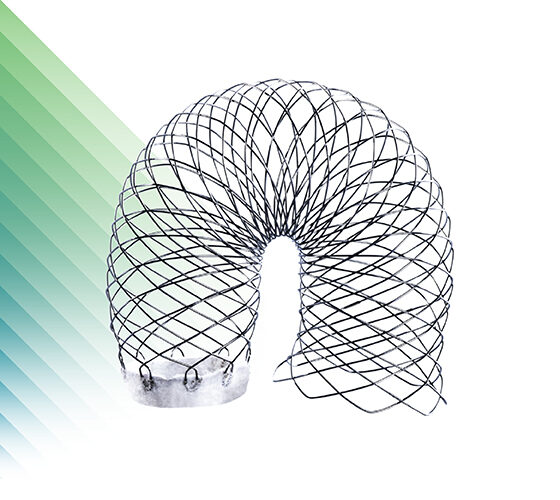

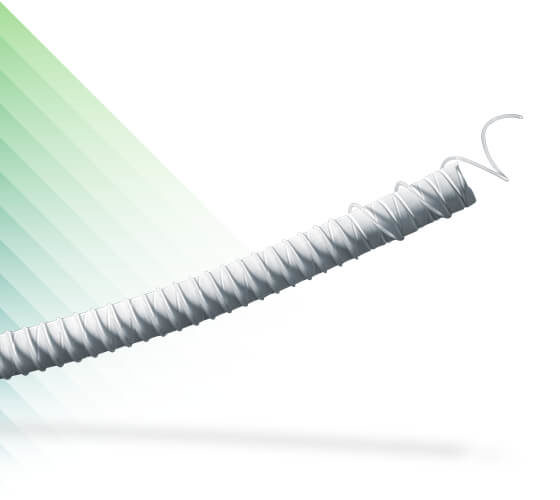

AMDS™

Hybrid Prosthesis

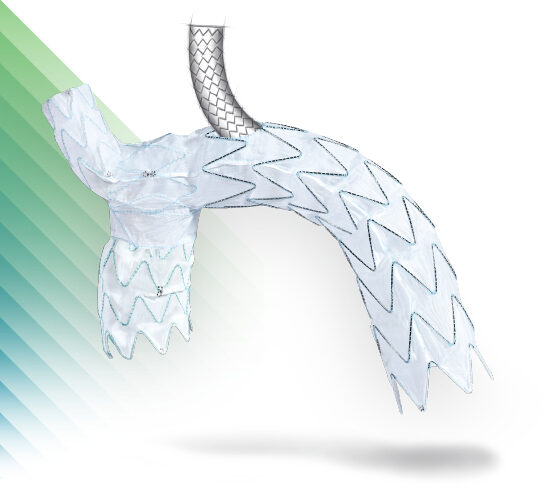

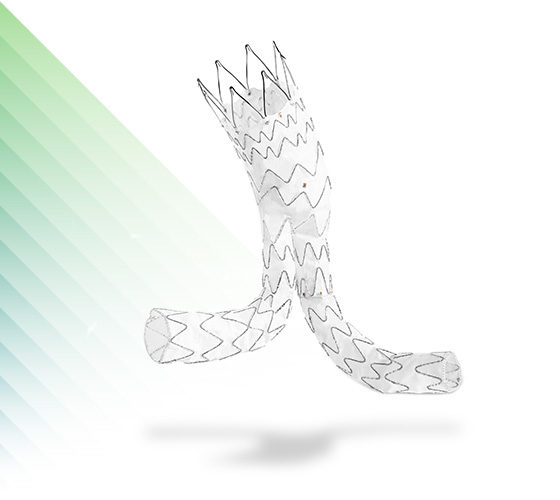

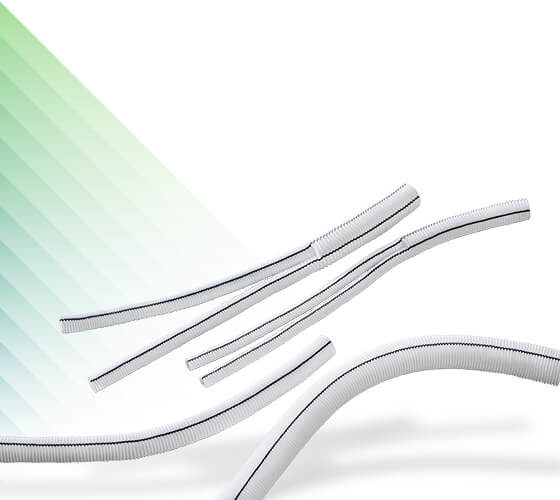

E-vita® Open Neo

Hybrid Stent Graft System

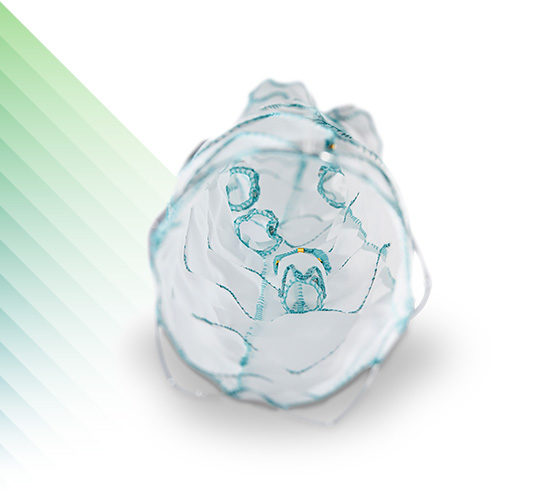

NEXUS®

Aortic Arch Stent Graft System

NEXUS DUO™

Aortic Arch Stent Graft System

Thoracoabdominal Solutions

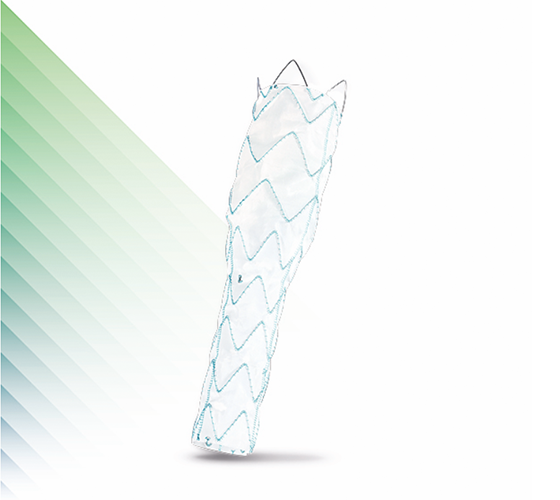

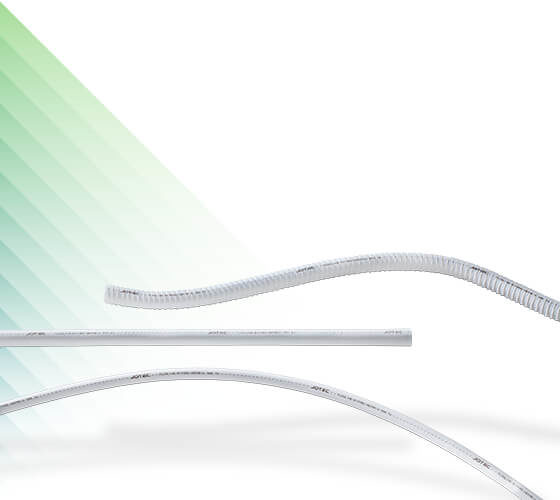

Artivex™

Thoracic Extension Stent Graft System

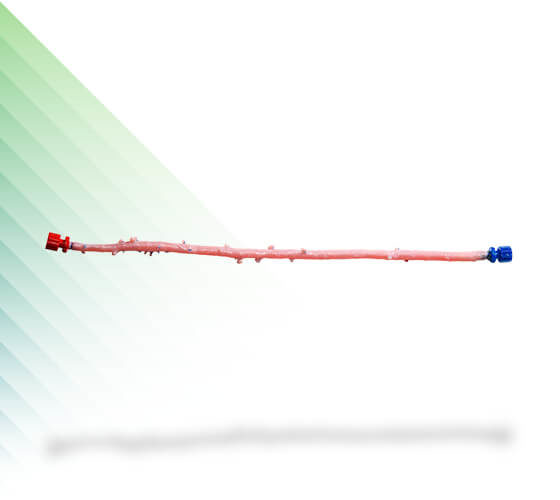

E-nside™ TAAA

Multibranch Stent Graft System

Abdominal Aorta Stent Grafts

Peripheral Aorta Stent Grafts

E-liac™

Stent Graft System

Surgical Sealant

BioGlue®

Surgical Adhesive

Cardiac and Vascular Ancillary Solutions

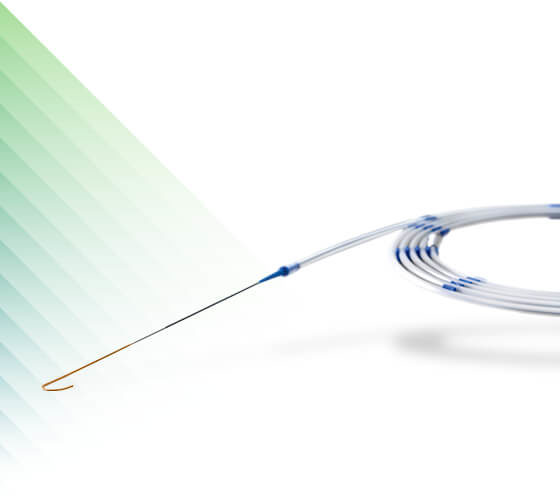

E-xtra Design Engineering

With our E-xtra Design MultiBranch Stent Graft System, we offer the option of having individual configurations that are tailor-made for the patient’s anatomy in the thoracoabdominal aorta. We have dedicated teams to help with planning, sizing, and implantation, so we can deliver your custom solution within 3 weeks of your request.*

*NOTE: This service is not available in the U.S. Delivery times vary by geography.

Over 5,000 successful implantations since the start of the program in 2012